BEST HEAT TREATMENT group of companies is founded by Shri.R.Nagarajan, a well known Techno-commercial in the field of heat treatment having a vast experience for more than 3 decades supported by skilled and dedicated workforce.

Best Heat Treatment Services

(BHTS) is the ideal place to find the suitable solution for all your metallurgical problems. BHTS provides the services of all kind of Heat Treatment like Stress Relieving, Through Hardening, All type of Annealing, Normalizing, Case Hardening,Carbonitriding, Liquid, Plasma & Gas Nitriding, Solution Annealing, Induction Hardening, Aluminium Solutionizing & Precipitation ( Ageing ) & Sub-Zero Treatment.

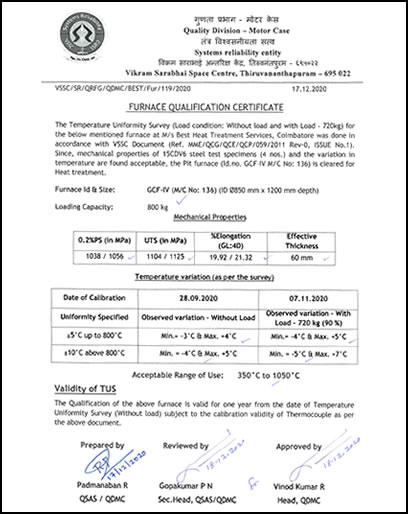

We have done the Heat Treatment process for the most leading automotive customers like M/s. Steel Industrial Forgings Ltd (Govt. of Kerala for Indian Railway & Brahmos), M/s. Ace Tech machinery components (for M/s. TAFE), M/s. BHEL & The furnace is approved by M/s. ISRO (VSSC – Trivandrum) & M/s. Godrej (Mumbai). And we would like to inform you that we were the first introducer of Sealed Quench Furnace & Plasma Ion Nitriding with full fledged Metallurgical Aboratory among the commercial heattreaters in Coimbatore.

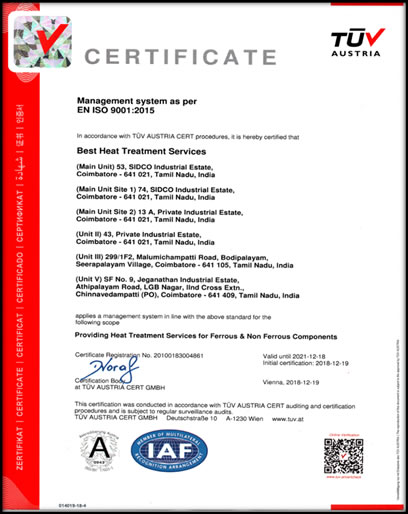

We have done the furnace calibration (TUS) by yearly once frequency & the other calibration like instrument, Inspection equipment’s by quarterly once frequency as per national & International standards (Ex:AMS 2750F, API6A & Annex M).

We have completed the heat treatment CQI9 job audit as per AIAG by yearly once( Internal ) & External customer CQI9 audit done by M/s. Caterpillar, M/s. TAFE , M/s. Ford , M/s. Royal Enfield, M/s. Pricol Ltd, M/s. Sandfits Foundries & API audit by M/s. GTN Engineering.

We have maintained 0% Rejection on process.

Quality Policy

“We are committed to achieve, sustain, and enhance customer satisfaction by providing quality components on time by continually improving the effectiveness of quality management system through team work of our organization”